Bioabsorbable Polymers

4D’s patented 4Degra® represents the next generation of bioabsorbable polymeric biomaterials for minimally invasive surgical devices, including musculoskeletal fixation devices, stents, films, soft tissue regeneration scaffolds and controlled-release drug delivery systems.

Bioabsorbable Polymers – a New Chemistry for a New Era

Bioabsorbable polymers for medical applications emerged in the 1960s and 1970s with the introduction of polyglycolic acid (PGA) and poly-L-lactic acid (PLLA) that enabled the creation of implantable medical devices that degrade away.

Over the years, this chemistry has been shown to have a number of shortcomings, including inflammatory responses, unpredictable degradation, biomechanical performance issues and processing and manufacturing limitations. (See a History of Bioabsorbable Polymers).

4D Medicine’s 4Degra®, formulated with 4D’s patented polycarbonate-urethane chemistry, overcomes these issues, representing a new era for implantable medical devices.

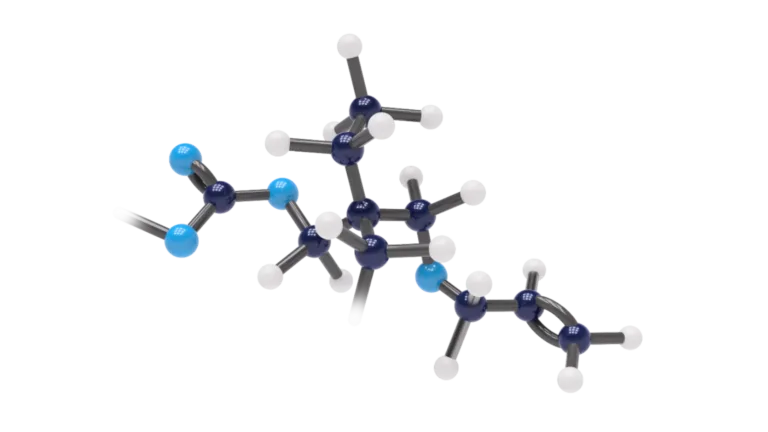

Introducing 4Degra® using polycarbonate-urethane chemistry

4Degra® has been designed at the molecular level with one purpose in mind – to deliver a better bioabsorbable material for implantable medical devices.

After more than 15 years’ rigorous academic research and development, 4Degra® resins, formulated with 4D’s patented polycarbonate-urethane chemistry, is capable of creating devices that meet a wide range of medical applications.

Five key properties of 4Degra®

Biocompatibility & Non-Toxicity

4Degra® is designed to degrade into benign, non-toxic byproducts that can be resorbed by the body without causing harmful reactions, making it highly suitable for implantation in tissues without the risk of long-term complications.

Tunable Mechanical Properties

The material’s mechanical properties, such as elasticity and strength, can be adjusted depending on the specific application. This tunability allows for the creation of both flexible and rigid devices.

Controlled Surface Degradation

Unlike bulk-degrading polymers, 4Degra® degrades in a controlled manner at the surface, which prevents rapid loss of structural integrity and ensures gradual, predictable absorption over time.

Shape Memory Capabilities

The polymer has shape memory properties, which are especially beneficial for devices used in minimally invasive surgeries. These devices can be inserted in a compact form and then expand to their intended shape, improving surgical outcomes.

3D Printing and Customisation

4Degra® can be processed via widely available 3D printing technologies such as SLA and DLP, allowing for the creation of highly detailed, custom-designed medical devices that are difficult to produce with conventional methods.

4Degra® potential applications

Select a button and click one of the circular hotspots to learn more about the potential applications of 4Degra®

Craniomaxillofacial devices

Upper extremity repair

& fixation devices

Hand & wrist repair

& fixation devices

Cardiothoracic devices

Spinal fusion devices

& bone regeneration scaffolds

Lower extremity repair & fixation devices

Lower extremity osteotomy devices

Foot & ankle repair & fixation devices

Aesthetic devices & injectables

Cardiovascular devices

Breast health devices

Soft tissue repair devices

Surgical membranes & meshes

Women’s health devices

Men's health devices

Neuro-oncology therapies

Subdermal drug-eluting devices

Anti-proliferative-eluting cardiovascular devices

Growth factor-eluting bone regeneration scaffolds

Antibiotic-eluting bone regeneration scaffolds & devices

Hormone-eluting devices

Find out more in our PDF:

4D is currently undertaking the regulatory groundwork to enable the use of 4Degra® in humans.

ISO 10993: This international standard evaluates the biocompatibility of medical devices. It outlines a series of tests and guidelines to assess how materials used in medical devices interact with the body, ensuring they are safe for human use.

The standard covers various biological evaluations, including cytotoxicity, sensitization, and irritation, to minimize risks of adverse reactions in patients. Testing is ongoing, with results anticipated in Q2/2025.

Pre-clinical studies: 4D is conducting multiple pre-clinical large animal studies to augment regulatory submissions. Early data (on file) is positive and supportive of material performance claims.

Interested in partnering with us?

4D has a number of significant private investors backing material science and medical device development. The company is also actively pursuing partnerships with novel medical device and sales channel organisations.